If you are in need of a new swimming pool filter for your commercial pool, waterpark, or aquatic center and you want to consider one of the most effective and efficient filters available in the aquatics marketplace today, you should consider a regenerative media filter. Although a regenerative media filter is not the best option for many aquatic facilities, our aquatic center and waterpark engineers & architects recommend considering this type of filter based on the pros and cons presented in this article.

“Our aquatic facility designers always advise facility owners to consider the pros and cons of all types of swimming pool filters, namely pressure sand filters, regenerative media filters, vacuum sand filters, and cartridge filters, before deciding on the best match to meet the particular needs of their aquatic facilities.”

There are many good reasons why regenerative media filters are making a considerable impact in the swimming pool industry today, but the most compelling is that these newly designed filters offer the same benefits we came to depend on from diatomaceous earth (DE) filters of the past, without the many operational drawbacks associated with handling dangerous DE material.

“Any longtime pool manager who has operated an old style DE filter will probably have a story to tell that involves airborne DE material, wrestling with the filter fabric or frames, and probably a few choice expletives mixed into the story that I will not repeat here.”

The regenerative media filters manufactured today are much different in comparison to older DE filters when it comes to how they operate and how filtration materials are handled.

How Regenerative Media Filters Work

Basically, regenerative media filters remove particles from dirty pool water by forcing the water through thin layers of powdery filter materials that capture the unwanted dirt, oils, and other nasty materials suspended in pool water.

It should also be noted that regenerative media filters are the only category of swimming pool filter that may capture viruses since viruses are too small to be effectively captured by more traditional sand filtration. Even though regenerative media filters may capture many disease-causing microorganisms that traditional sand filters will not, ultraviolet (UV) treatment of the pool water, in addition to effective filtration (including that of sand filters), is the most effective way to ensure destruction of such dangerous particles with the highest degree of certainty.

All regenerative media filters use a powdery coating material such as diatomaceous earth or perlite to filter unwanted elements from the swimming pool water. Diatomaceous earth (DE) is a fossilized material that is mined and refined for use as a filter medium. Perlite is derived from volcanic rock that is superheated to create the powdery substance used in filtration. Both of these substances consist of small particles that have large surface areas, in relation to their overall size, to capture the unwanted materials in pool water. Please note that wherever perlite is mentioned in this article, DE can be substituted. Perlite however, is the material recommended for use with most modern regenerative media filters.

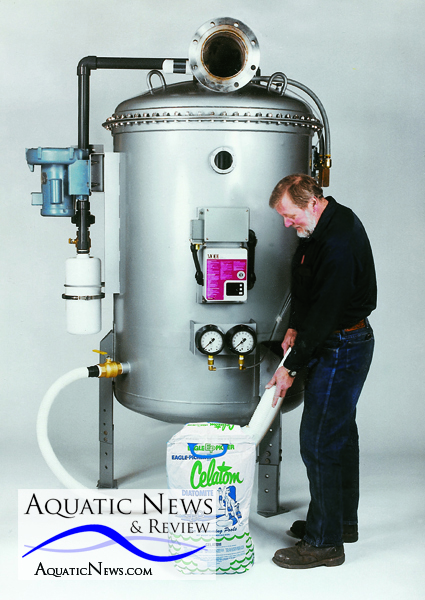

With regenerative media filters, perlite material is added to the filter chamber through a vacuum hose or slurry funnel. Once the material is in the filter chamber, pool water is introduced into the tank and the mixture flows toward outlet tubes that are covered with a polyester woven fabric covering. This covering is coated with the perlite material as the water/perlite mixture flows from the filter chamber through these outlet tubes. This process of the water/perlite mixture coating the outlet tubes is referred to as the “pre-coat” cycle.

During the pre-coat cycle, the filter pump pushes the water/perlite mixture all around the flex tubes until the tubes are entirely coated with perlite and the water exiting the filter is completely clear. At this point, valves are opened to the pool and full filtration of pool water begins.

As dirty water from the pool enters the filter chamber, the dirt, oils, and other microscopic elements in the water are all trapped in the perlite material on the outlet tubes. Clean water passes through the perlite material, into the outlet tubes, and back into the swimming pool.

According to manufacturer’s literature, regenerative media filters may remove particles as small as 1 micron in size from the pool water. When compared with removal of particles in the 15 to 20 micron range with traditional pressure sand filters, this is spectacular particle filtration.

As dirt products are captured in the perlite coating, the amount of pressure required by the circulation pump to maintain a given flow rate starts to rise. When this happens, the filter begins a “bumping” cycle followed by another pre-coat cycle. On most regenerative media filters, this bumping cycle occurs automatically through the use of compressed air and a rubberized air bladder that quickly raises and lowers the filtration tubes inside the filter.

For a more detailed discussion of the regenerative media filter cycles, feel free to contact our independent aquatic facility engineers.

During the bumping cycle, the outlet tubes with the dirty perlite coating are shaken with just enough force to knock off the perlite coating back into a solution with the water in the filter. This water/perlite mixture is in effect “remixed” through the action of the flowing water before naturally re-coating the polyester fabric on the outlet tubes with newly arranged perlite material. Even though the perlite in this second coating contains dirt from prior use, it remains extremely effective at filtering the swimming pool water and only clean, filtered water is returned to the pool.

(see the video below for an illustration of the bump cycle)

This “regeneration” of the perlite material for use in multiple cycles is where the term regenerative media filter comes from. Most pool operators know from experience that a dirty filter actually does a better job of cleaning water than a clean filter. The reason for this is that dirt fills voids in the filter medium and effectively blocks smaller and smaller particles in the water as the filter becomes dirtier. A filter eventually has to be cleaned, or “backwashed” in the case of a sand filter, in order to continue filtration without the need for more and more water pressure from pumps to push the dirty water through the filter.

In the case of a DE or perlite filter, the particles are so small from the start that only very small particles in the pool water, in the 1 to 5 micron range, can penetrate the material even when it is first introduced as new into the filter.

The regenerative cycles of the filter, bumping, pre-coating, and then filtering, all continue as needed to filter the pool water until a point is reached where even after a bumping cycle the pressure required to push more water through the filter is too great. When this pressure set point is reached, the entire volume of the water in the filter is dumped and a fresh batch of perlite is vacuumed back into the filter and the process starts anew.

The length of time between intervals of dumping old material and addition of new perlite material all depends on how heavily the swimming pool is used and the amount dirt, oil, and other material that is introduced into the filter. This dumping cycle typically ranges from once a week to several weeks depending on pool usage. The good thing is that no matter how often the perlite material is replaced, the pool will get several “regeneration” cycles of the material and the purity of the water being sent back to the pool is the same high quality all of the time.

Pros of Regenerative Media Filters

The regenerative media filter has inherent qualities that make it a good choice for many swimming pool applications.

Filtration of Extremely Small Particles:

First, is the wonderful job it does of actually filtering the water. As has been stated earlier, regenerative filters are capable of filtering out materials as small as the 1 to 5 micron size range. Filtering water to this level results in extremely clean and clear water.

The more material a filter removes from swimming pool water, the less material there is in the water that must be disinfected or oxidized by chemicals in the water, such as chlorine. The end result is cleaner water with lower amounts of chlorine needed to maintain proper free available chlorine levels of 1 to 3 ppm. This should result in somewhat lower chemical costs.

Another benefit of filtering such small particles is the removal of parasites such as cryptosporidium (crypto). In a swimming pool, fecal accidents may introduce this highly contagious parasite into the pool. Unfortunately, safe levels of chemicals in the pool will not effectively kill much of this parasite without a very long contact time period. Essentially, this is what makes an outbreak of crypto so harmful in a pool, resulting in the potential for making people violently sick.

With treatment systems that include regenerative media filtration for these small microorganisms (crypto is on the order of 3 to 5 microns in size), most of these harmful creatures will be captured and removed from the pool water. Traditional sand filters will rarely capture these tiny microorganisms. It must be noted that other technologies such as UV are the most effective at killing crypto. If you combine great filtration with UV treatment of all water returning to the pool, you will have the most effective treatment system possible for killing disease-causing microorganisms such as crypto.

High Level of Water Conservation:

Water consumption is another significant benefit of regenerative media filtration over traditional sand filters. The only water loss associated with the regenerative media filter is the volume of the filter tank itself. When it is time to replace the perlite material in the tank, after several regenerative cycles, the volume of an entire tank is wasted twice to ensure removal of all dirty perlite. This water loss is magnitudes less than with a traditional sand filter that requires a backwash rate generally equal to the filter flow rate for a period of 3 to 5 minutes. With a sand filter this must occur every time the filter needs to be backwashed.

Traditional Sand Filter: Backwash every third day at 1,000 gpm for 5 minutes = 5,000 gallons or 1,667 gallons per day

Regenerative Media Filter: Bump cycle every day at 0 gallons of water loss. Empty tank after 7 days at 2 tank volumes of 441 gallons each = 882 gallons total or 126 gallons per day

In the example above, it is easy to see how the regenerative media filter uses much less water. Water savings such as this have a significant impact on water conservation measures, the actual cost of water, the cost of pool chemicals needed every time new water is added to the pool, and the cost of energy to heat the new water as may be applicable in some pools.

You can also see how such a dramatic decrease in backwash water will result in lower sanitary sewer costs as well. With the smaller quantities of waste water produced by regenerative media filters, costs associated with large holding tanks and sewer lines are also significantly lower.

Cons of Regenerative Media Filters

As with every type of equipment in the swimming pool industry, there are a few drawbacks.

Externally Loaded Media Required

Unlike sand filters, regenerative media filters require externally loaded filter media on a periodic basis. Sand filters eventually require replacement of the sand, but this is only after many years of heavy use. Regenerative media filters require new media such as DE or perlite after several cycles of use.

It must stated however, that the changing of this material in modern filters is relatively easy. In the old days, handling DE with old style filters was a messy and somewhat hazardous process. The hazardous part of the process occurred when pouring the material into the filter tank. When pouring from a bag, the material can become airborne with the potential of being inhaled (take it from me, not a pleasant experience).

In the new regenerative media filters, the danger of airborne media that can be inhaled has been virtually eliminated with the use of direct vacuum into the enclosed filter tank from the bag containing the media.

Another drawback is the cost of the media itself. A bag of perlite needed to adequately fill an average sized filter will cost around $40. Keep in mind that a new bag is only needed after several regeneration cycles and will amount to a few dollars per day.

Does Not Work as Well with High Oil Concentrations in Pool Water

Another drawback can be use of these filters for swimming pool water containing high concentrations of oils, such as with highly used outdoor swimming pools or waterparks in the summer.

Most of the oils come from sunscreen lotions, and these tend to result in a caking effect with the perlite at times. If the perlite material begins to cake, it is harder for water to pass through the filter which results in more frequent “dumping” cycles and fewer “bumping” cycles as described above.

Before specifying a regenerative filter for an outdoor pool, your independent aquatic center consultant / designer should fully evaluate the anticipated bather loads and profile of use to determine the filter’s effectiveness for the application. This is not to say that regenerative media filters are for indoor use only, just that a thorough evaluation is needed before specifying any particular product.

Typically Higher Initial Capital Costs

Probably the biggest drawback to a regenerative media filter is the initial cost of the filter. Initial filter cost can be somewhat higher than with a traditional sand filter. To last through decades of pressurized use, most regenerative media filters are constructed of steel with specially designed coatings for the swimming pool industry.

Even given the higher initial cost of the filter compared to more traditional sand filters, regenerative media filters can have a payback period of just a few years because of the ongoing cost savings. After the payback period has been reached, the aquatic facility should enjoy continued savings. Many factors go into determining the payback period you may or may not realize from use of regenerative media filters. We recommend consultation with aquatic facility architects and engineers to help with decisions related to the best filters for your particular aquatic facility prior to final selection.

Manufacturers of Regenerative Media Filters

As of today, there are 2 major manufacturers of regenerative media filters for the commercial swimming pool industry. They are as follows:

Neptune Benson – utilizing flexsol 3000 lined carbon steel construction

Paddock Industries – utilizing stainless steel construction

Conclusions and Recommendations for Regenerative Media Filters

For a while after the first regenerative media filters appeared in the aquatics marketplace, our aquatic facility design firm avoided their use on our projects because of the higher initial costs of the filters and the lack of a proven effective track record.

“We never allow aquatic facilities we design to be “guinea pigs” for unproven technologies. We always thoroughly evaluate technologies before considering them for our clients’ aquatic facilities.”

Over the years however, many facilities have installed these filters with great success. After evaluating the track record of these filters for ourselves, we have started incorporating some into our aquatic firm’s designs whenever our analyses prove such filter technology is warranted and best for the particular aquatic facility.

Our recommendation to those looking to build a new or renovated aquatic facility is to seriously consider using regenerative media filters as one of your options, especially if lower water consumption and highly effective filtration is a goal.

Please note that none of the contractors or manufacturers listed in this article have paid for such mention. We are including this information for the sole benefit of our readers to help them make informed decisions about their aquatic facility needs. If you need more information or help with your aquatic center, commercial swimming pool, or waterpark project, please contact our expert aquatic facility designers for more information.